Black spots and impurities on injection molded parts not only affect the appearance, but also reduce product performance and even cause potential safety hazards. So, where exactly do these annoying black spots and impurities come from? And how can we avoid them?

This article will provide an in-depth look at the causes of black spots and impurities in injection molded parts, and provide a range of practical ways to help you create flawless injection molded products.

Where do black spot impurities come from?

The sources of black spots and impurities in injection molded parts are complex, and to avoid black spots and impurities in injection molded parts, it is necessary to start from raw materials, production environment, injection molding process, equipment maintenance and personnel management and other aspects to carry out comprehensive control.

- Raw material problem: The raw material itself carries impurities or high temperature decomposition produces impurities.

- Production environment problems: dust, equipment contamination and human factors in the production environment lead to impurities mixing.

- Injection molding process problems: impurities caused by improper injection molding parameters, mold design defects, and poor equipment maintenance.

- Equipment maintenance problems: equipment wear, aging, damage and impurities.

What are the steps of injection molding that are prone to impurities?

In the process of injection molding, the following links are easy to introduce impurities. Strict control of cleanliness in production can effectively reduce the generation of impurities.

- Raw material storage and transportation: Unclean storage and transportation environments can lead to impurities in raw materials.

- Raw material feeding: impurities are introduced by incomplete cleaning of feeding equipment or improper human operation.

- Barrel & Screw of Injection Molding Machine: Molten plastic contamination caused by residue or wear debris from the barrel screw.

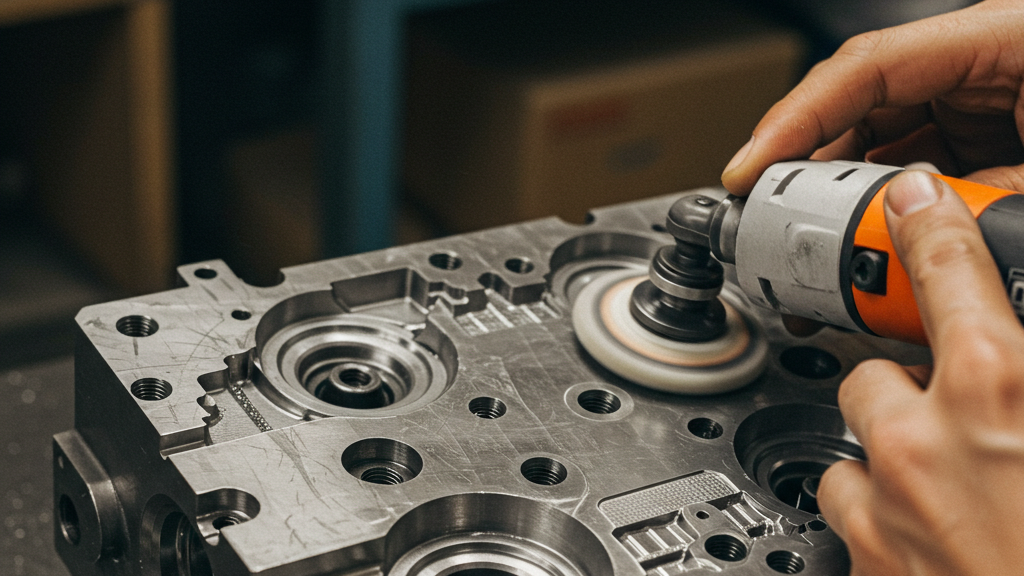

- Mold: impurities caused by dirt on the surface of the mold, impurities in cooling water or wear and tear on the mold itself.

- Production workshop environment: Dust from the workshop or dust generated by other production activities contaminates the injection molded parts.

How to technically reduce impurities?

In injection molding, impurities can be reduced by optimizing process parameters, improving mold design, and employing filtration technology. Improve product quality and production efficiency.

- Optimize injection molding process parameters: Precisely control temperature, pressure and speed during the injection molding process to avoid material decomposition and impurities.

- Improved mold design: Reduce impurity retention and generation by optimizing mold runners, increasing venting, and improving surface treatment.

- Advanced filtration technology: molten plastic and air filters are used to effectively remove impurities from the production process.

- Improve the level of mold maintenance: regularly clean, check the mold, carry out maintenance, and reduce the impurities generated by the mold itself.

Analysis table of the causes of impurities

|

Types of impurities |

Causes |

Precautionary measures |

| Black spots/carbides | Decomposition at too high temperature. Staying too long. | Control the temperature. Optimize injection speed. |

| Heterochromatic impurities | Mix of materials. Poor quality of masterbatch. | Strict control of materials. Choose high-quality masterbatches. |

| Metallic impurities | Wear and tear of the equipment. Raw materials are mixed. | Maintain the equipment regularly. Inspect raw materials. |

| Dust/fibers | The environment is unclean. The packaging is damaged. | Keep the workshop clean. Check the packaging. |

Causes and prevention of black spots and impurities

Black spots and impurities in injection molded parts are important factors affecting product quality. It is essential to understand the causes and take effective preventive measures. The following methods can be effectively prevented.

1.Raw materials: Pollution and decomposition of raw materials are important sources of impurities.

2.Production environment: The dust of the production environment and the unclean equipment will directly lead to the mixing of impurities.

3.Injection molding process: Improper injection molding process parameters are the key factors causing impurities.

4.Equipment maintenance: Strengthen equipment maintenance and regular cleaning, which can effectively reduce the risk of impurities.

conclusion

Through systematic control and optimization, can significantly reduce the generation of black spots and impurities in the injection molded parts. This not only improves the overall quality and market competitiveness of the product, but also ensures that the product meets higher industry standards and customer expectations.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-06-2025